VCarve Pro

VCarve Pro tarjoaa tehokkaan mutta intuitiivisen ohjelmistoratkaisun osien luomiseen ja leikkaamiseen CNC-jyrsimellä. VCarve Pro antaa sinulle mahdollisuuden tuottaa monimutkaisia 2D-kuvioita profiili-, tasku-, pora- ja upotustyöstöradoilla, sekä antaa sinulle mahdollisuuden luoda malleja v-carving-kuvioilla sekä tuoda ja koneistaa rajattomasti Vectric 3D -leikekuvioita tai yksittäisiä mallitiedostoja. "Pro"-versio tarjoaa sinulle rajoittamattoman työ- ja työstöradan koon, todellisen muodon sisäkkäiset ja työasetussivut, jotka sopivat ihanteellisesti tuotantoympäristöön.

Complete set of 2D Design and Layout Tools

Easily create vectors from scratch or import and edit bitmap images

Create 2.5D Toolpaths

Including; V-Carving, Prism Carving, Mouldings, Textures & Fluting

Import and machine single 3D models

Including; STL, OBJ, 3DM and SKP file types

$2000 Worth of Free Clipar

Includes 2D and 3D Clipart that can be used in your own projects or edited to create new variations

Unleash Your Creativity with VCarve Pro

2D Import & Editing

VCarve Pro can import 2D designs from other programs but also provides a full set of drawing and editing tools.

2D & 2.5D Toolpath Option

The toolpath options cover all typical 2D routing operations such as Profiling, Pocketing, Auto-Inlays, Drilling and Thread Milling as well as 2.5D strategies.

3D Rough & Finish

For 3D you can Rough and Finish the model and there are options to project 2D and 2.5D toolpaths onto the 3D surface.

Customize & Control

Each toolpath includes appropriate options to customize the settings and provide a high level of control for different types of operation.

3D Model Import

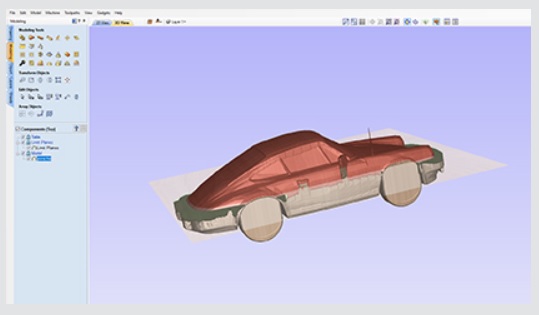

VCarve Pro includes the ability to import multiple Vectric 3D models as well as a single 3rd party model, where they can be assembled to suit your design.

Instant Preview Updates

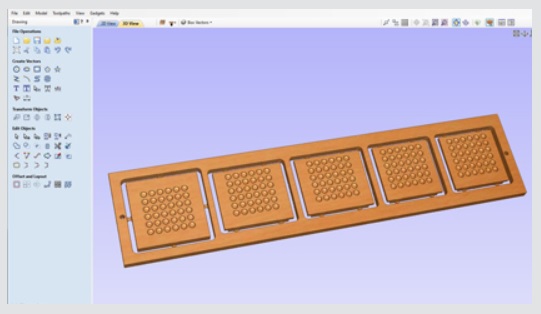

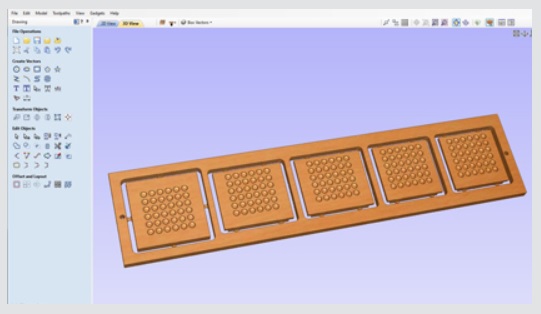

All toolpaths can be previewed to show just how the part will look when it is actually cut, this allows instant feedback to allow toolpaths to be further optimized.

Machine Parts on Two Sides

Two-Sided Machining adds the ability to create double-sided projects in the same session. It avoids the need to have 2 sessions, one for each side.

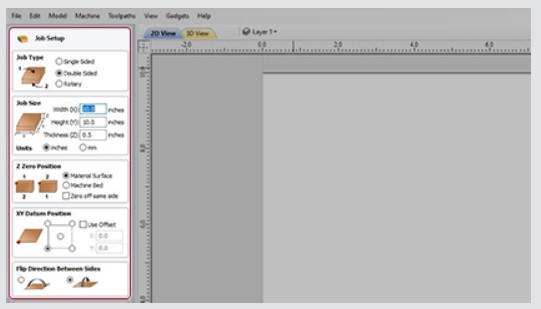

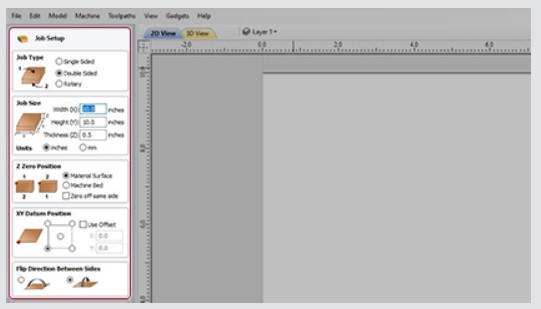

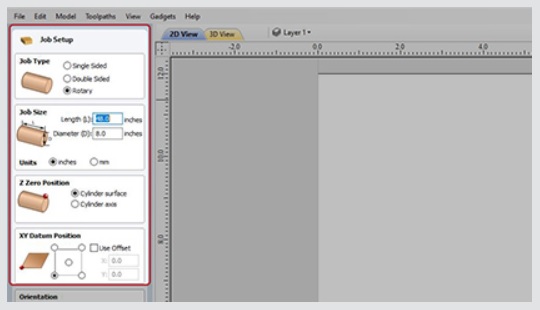

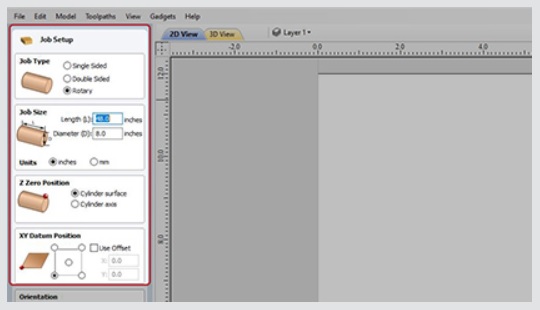

Job & Material Setup

In the Job Setup dialog, you can pick whether you want to create a single-sided, double-sided or a rotary job. You can change that, retrospectively.

Define how you want to flip the material for double-sided projects from the Job Setup dialog. This influences the positioning of the vectors and models so that geometry on each side is created in the appropriate positions relative to the opposite side.

Multi-Sided View

You can view the opposite side’s geometry using the keyboard shortcut ‘=’, or through the ‘View’ menu.

In the 2D view, you will see the opposite side’s vectors as if you were looking at them through the material block.

In the 3D view, you will see the entire merged model as if it was simulated.

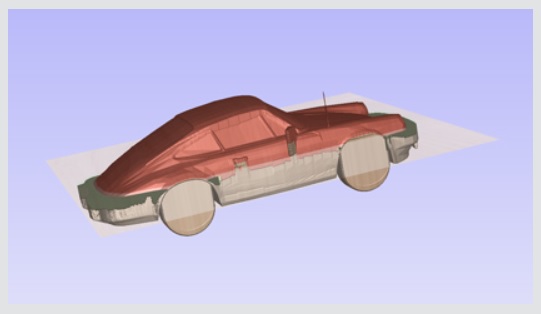

Importing STL Model

When importing an STL model (with the ‘Import both Sides’ option enabled) into a double-sided project, each side of the model will go onto a side.

You can import the entire model on each side by sliding the slicing plane all the way to the bottom. This is useful when importing models which contain non-convex surfaces, such as, a plate.

Machine Wrapped Rotary Parts

Enables the use of a rotary axis (also called a 4th axis or indexer).

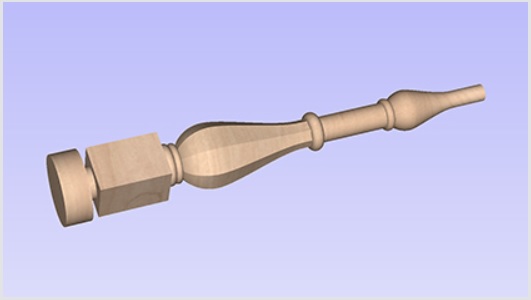

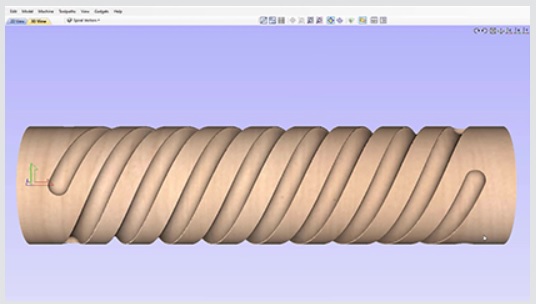

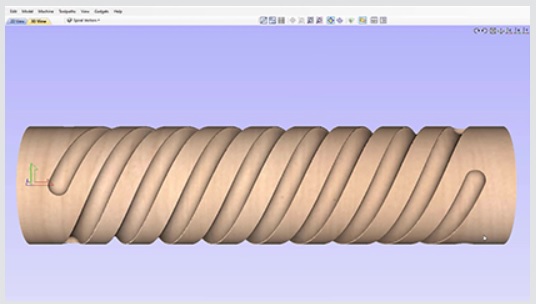

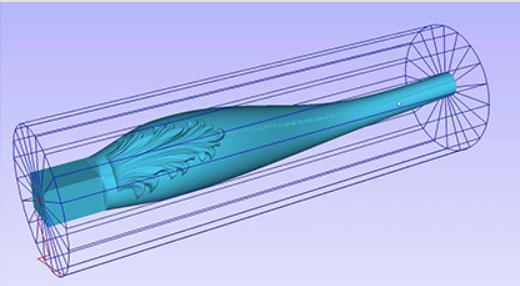

Wrapped Rotary Machining

Enables the use of a rotary axis (also called a 4th axis or indexer). Where you can create rotary projects and visualize your job in a wrapped environment, with the ability to create and simulate the toolpaths in an auto - wrapped simulation.

Rotary Job and Material Setup

Rotary Job and Material Setup

In the Job Setup dialog, you can pick whether you want to create a single-sided, double-sided job or a rotary job. You can change that, retrospectively.

Define your cylinder dimensions, the orientation of the job, how the 2D view will be laid out, and which axis we're wrapping around.

Spiral Toolpaths

In order to create a toolpath that wraps around multiple times, one can create a long vector at a certain angle. Such a vector is an equivalent to the strip of fabric when it is unwrapped from the roll.

Although such a toolpath will exceed the 2D workspace of the rotary job, thanks to the wrapping process during both simulation and machining the toolpath will actually stay within material boundaries.

Model Import into Rotary Project

The software has the ability to import full 3D models from third party software for unwrapping in a rotary job, where you can position and orient the model in a rotary view.

Not only can you import full 3D models for unwrapping the software also allows for the importing of "Flat 3D" models (relief style models) that you can position and simulate before cutting.

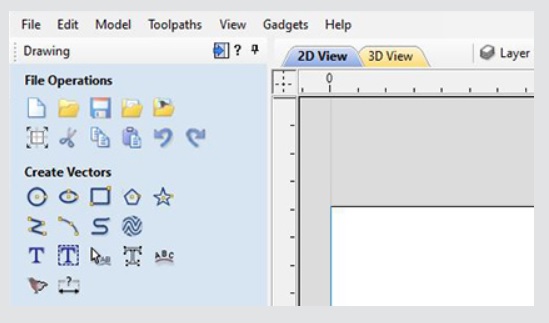

Drawing & Layout Tools

The software has a comprehensive set of drawing tools to let you easily create vectors from scratch or add to imported data.

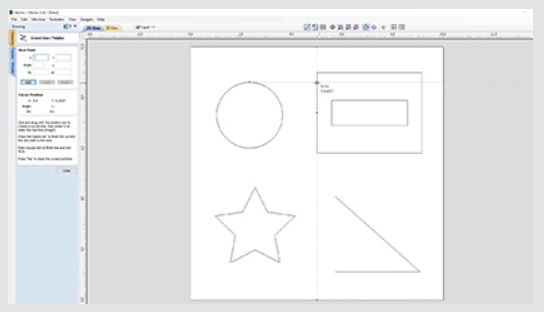

Vector Shape Creation

The software has a comprehensive set of drawing tools to let you easily create vectors from scratch or add to imported data. These include options for creating standard shapes (circle, elipse, rectangle, polygon and star) along with line, curve and arc drawing tools. There is also a powerful tool to create vector textures for panels and backgrounds. These tools can be controlled using typed input to create exact sized objects or can be used dynamically with the mouse to sketch your artwork. The tools also take advantage of the 'snapping' to let you use points on existing objects to 'snap' onto when you are drawing vectors.

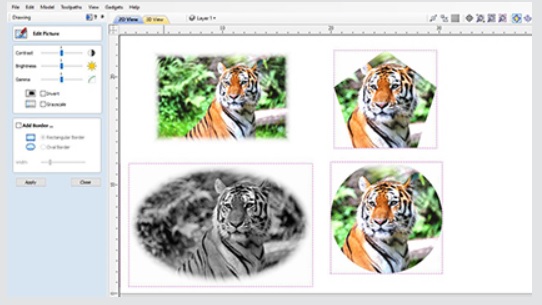

Picture Editing & Cropping

With the ability to import bitmaps into the software, you can further edit imported images using the 'Edit Picture' tool, this allows you to adjust the visual properties of a selected bitmap, enabling you to adjust the contrast, brightness and gamma of any selected image.

Borders of different sizes and radii can also be added to bitmaps for aesthetic purposes. Bitmaps can also be made black and white. The software also has the ability to crop images to any given vector allowing you to remove parts of the image you are not interested in.

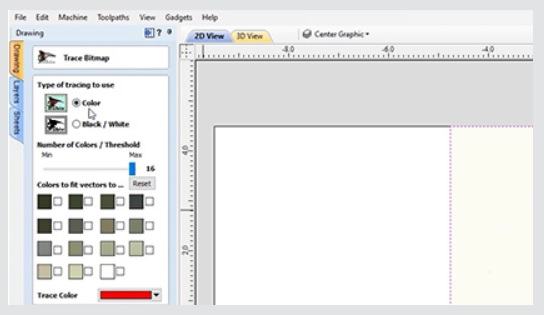

Image Tracing (Vectorization)

Image tracing also known as vectorization allows you to take an imported image such as a scanned drawing, graphic design or photo and to convert colors in that to vector outlines. These outlines can then be used as part of your design to create toolpaths or to generate 3D shapes using the modeling tools. The software will import many file formats including jpeg, bitmap, gif, png, tif, it will also extract images from a PDF file.

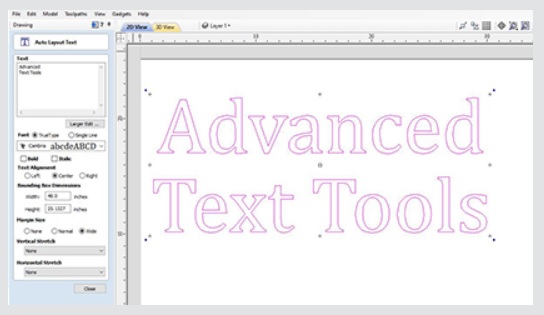

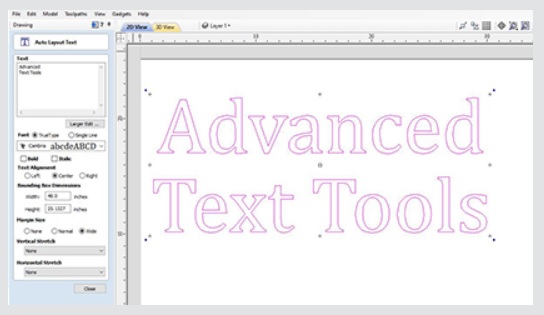

Advanced Text Tools

The 'advanced text' tools let you access true type or open type fonts on your PC to create text outlines for your design. In addition, the software comes with a selection of specialist single stroke / stick engraving fonts for efficient machining when making things like badges or small signs.

When creating text you are able to see live feedback of the text that you create and edit. The text can be controlled using automatic sizing and layout options. There is an inbuilt spell checker where errors will be underlined in red, where you are able to locate the correct spelling as well as having the ability to add words to the software’s dictionary too!

There are also editing tools for fitting text to a curve and interactive text arcing and spacing (kerning) where the text maintains formatting, allowing you to easily make edits after the text has been created. This text can be dragged dynamically along a curve so you can perfect the placement of your text.

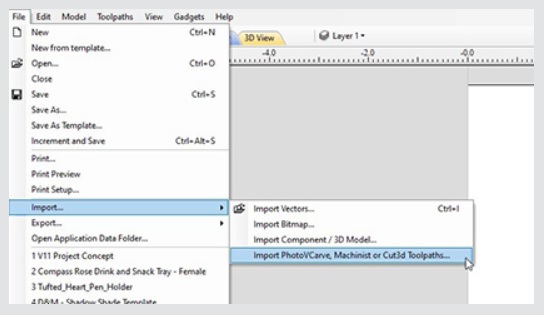

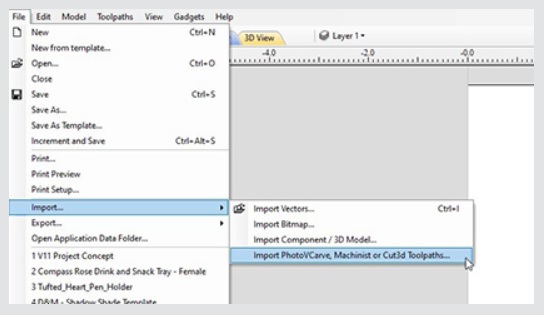

Import 2D Data (DXF, DWG, EPS, AI, SKP, SVG etc.)

Data can be imported from a huge range of other design programs using a variety of industry standard file formats. These include DXF, EPS, AI, SVG and SKP (SketchUp) as well as PDF files. Once imported, the program has a wide range of tools to make working with this data as efficient as possible.

A very important set of tools are those used to identify duplicate vectors and identify and rejoin open vectors. These tools can save an great deal of time when working with poor quality data to get it ready to machine.

As well as importing vectors from other programs the software also offers the ability to export your data in either DXF, EPS or AI file formats. This feature is very important if you need to share data with a customer in order that they can use it to plan a layout or installation.

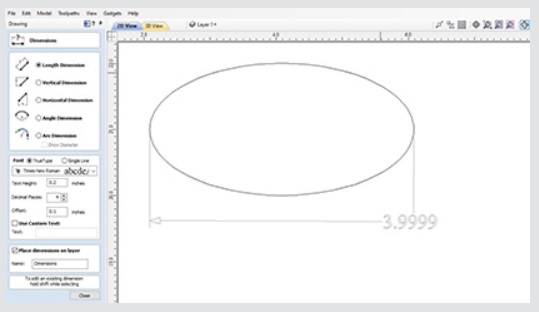

Basic Dimensioning

The dimensioning tools allows you to create a variety of different types of measurements on your drawing. These can be oriented in any direction or fixed horizontally or vertically. There are also options to add angular and arc dimensions. You can control the text height, font number of decimal places and position for each one. Dimensions can be snapped to vectors, guidelines and the corners or mid-points of each side of your work area.

Vector Transform & Editing

Whether your design vectors have been created in the software or imported you have a large choice of editing options to prepare your part for toolpath creation or modeling. Vectors can be easily scaled, moved, mirrored, distorted, grouped, welded, trimmed, filleted, extended, offset, smoothed and joined together. As with the drawing tools you either have precise control over the editing values adjust the vectors very accurately or can use the mouse to dynamically make adjustments until your layout looks correct.

Vector Layout

In addition to the editing tools the software also has tools to let you layout parts either in a rectangular array to create a grid of objects or in a circular array to create symmetrical layouts around a center point. When laying out a grid you can adjust mirroring options and shift alternate rows and columns to make more complex layout patterns.

Vector shapes can also be pasted along the path of another vector by specifying the distance between each copy or just fitting a specific number on the guiding object.

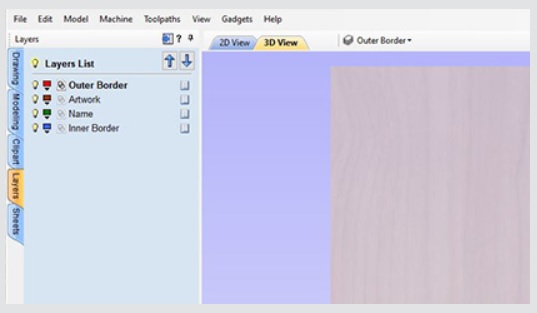

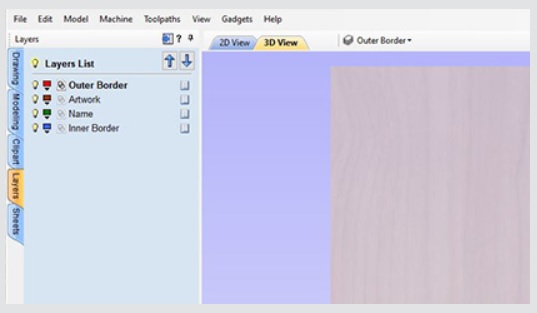

Layer Management

The Layers are a very efficient way to keep your 2D data organized, one of the main uses is to allow you to temporarily hide data you were not currently working with. Layers could also be used to group vectors you might be using to model related shapes in a 3D design to make it simpler to work on a small part at a time.

The ability to associate toolpaths with specific layers and types of data means you can create Toolpath Templates which can be assigned to other parts that share the same layer structure. This is particularly powerful for applications like Cabinet Making where different designs can be automatically machined once a template has been set-up.

Multi Sheet Support

Not only can you organise your design onto layers but you can also make use of multiple sheets in your projects to help manage and organise your work on a per sheet basis when working with multiple materials in your designs. Each sheet can have it's own dimensions and settings, making it an ideal solution for when you are working on a project that requires multiple materials. The sheets tab lists all of the current sheets and allows you to create, update and delete them. You can create sheets of different sizes and thicknesses as well as having the ability to control the material appearance for each sheet to better visualize your toolpaths as part of the overall project. All sheets within a project can be managed individually or collectively, making it simple to resize or update a specific selection of sheets.

Rulers, Snap Grid and Guidelines

Rulers, Snap Grid and Guidelines help to make vector drawing and 3D part layout much simpler. These options can be switched on / off as required. When combined with Snapping options that automatically detect and snap the cursor to key regions on a design these tools make it easy to create very accurate part.

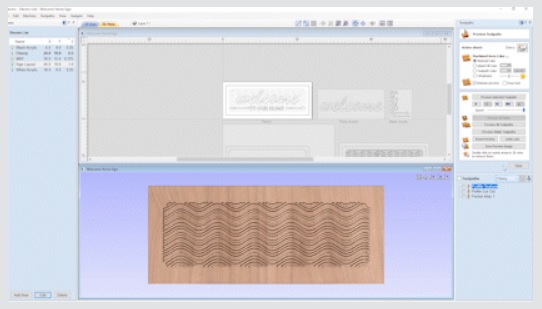

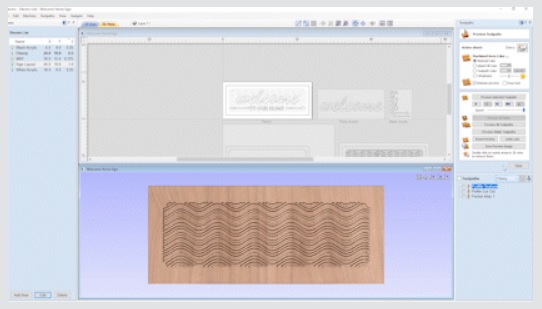

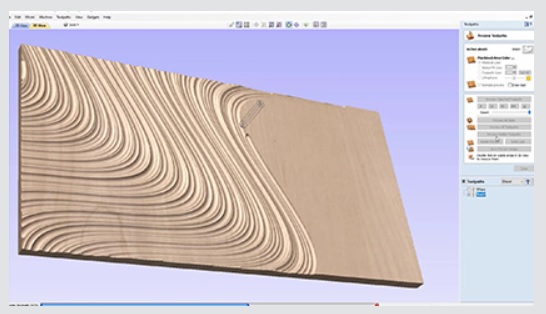

Create Vector Texture

Repeating vector patterns can be quickly created using the 'create vector texture' tool. It's easy to modify the settings to create an infinite number of variations from regular wave patterns through to uneven natural looking grain lines.

These vectors can be machined using the profile and texture toolpaths to create decorative wavy texture panels along with wood-grain and sand-blast effects. These can also be projected onto a 3D surface to add even more variation.

Smart Snapping

This allows you to snap to lines and extensions, which don’t necessarily exist as geometry. It reduces the need to create construction geometry, and would be helpful in aligning vectors or nodes.

Quick Keys

This allows you to add more precision to your shape creation and editing process more easily by allowing typed values while creating geometry. This is supported for creation of circles, ellipses, rectangles, polygons, stars, polylines and when in editing nodes or transforming vectors.

For example, while dragging to create a circle, you could type ‘3R’ to create the circle with a radius of 3. Or, also while dragging, you could type ‘3D’ to create one with a diameter of 3.

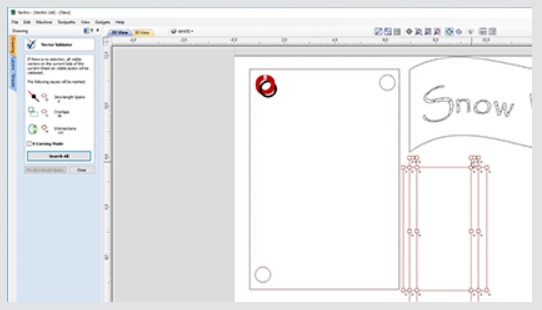

Vector Validator

The Vector Validator is intended to help find issues with contours after file imports that are stopping tool-path creation such as overlapping contours or intersections. It also indicates zero-length spans.

3D Assembly

Import multiple Vectric Clip Art 3D models (V3M) to create advanced 3D assemblies.

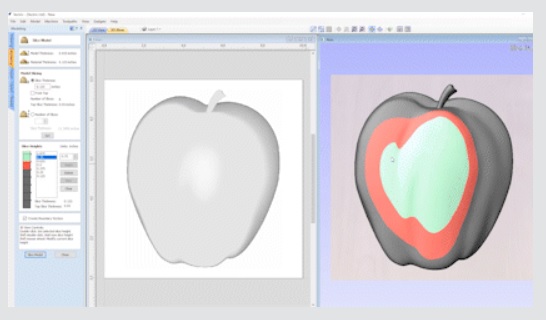

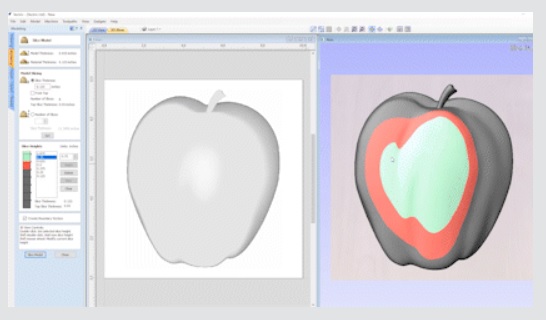

Import 3D Models (STL, OBJ, 3DM etc.) & Clipart (V3M)

Import a single 3D mesh file created in other CAD software such as,

Rhino 5, SolidWorks, AutoCAD, Silo, MOI, Blender, SketchUp etc.

STL, 3D DXF, OBJ, 3DS, VRML, 3DM, SKP file formats

Interactively change the size and orientation of imported 3D models.

Interactively rotate 3D mesh files into the required orientation for adding to a design.

Instantly convert designs from raised models to recessed mold cavities.

Easy to use interactive drag and drop, size, mirror and rotate tools allow 3D clipart designs to be edited to instantly produce unlimited design variations.

3D Component Editing

Shapes can be easily scaled, moved, mirrored and grouped. You can also create a vector boundary around selected components which is useful for when you want a boundary vector of the composite model. VCarve also allows you to smooth a 3D object using the smooth tool.

Relief Slicing

The software has a tool to Z-slice a part to create separate models if your CNC size, tooling or material limits the depth of part you can cut. Where you are able to choose the thickness of individual slices, where they can be tweaked and visualised in the 3D view to give you maximum control of how your model is sliced for machining. This helps to ensure that there are no thin slices that can be problematic from a machine and assembly point of view.

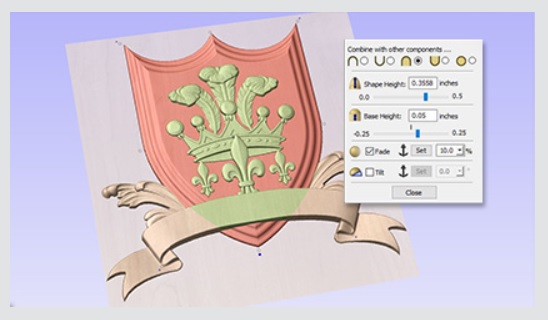

3D View Component Manipulation

Many of the dynamic component editing tools can be accessed directly from the 3D view. This allows 3D objects to be moved, scaled and rotated. In addition how they combine with other shapes can be adjusted along with their height and even adding a tilt or fade.

Editing the components in the 3D view makes it quick and easy to see the immediate effect of the changes to the composite model and so reduce the time it takes to create a 3D layout.

Ota yhteyttä

Ota yhteyttä ja kerro mitä lisätietoja haluat tästä tuotteesta